Sort:Company News Release time:2025-03-31 275Views

—Redefining Ultra-Large Gas Carrier Equipment with China’s Intelligent Manufacturing

[Zhenjiang, China – March 31, 2025]

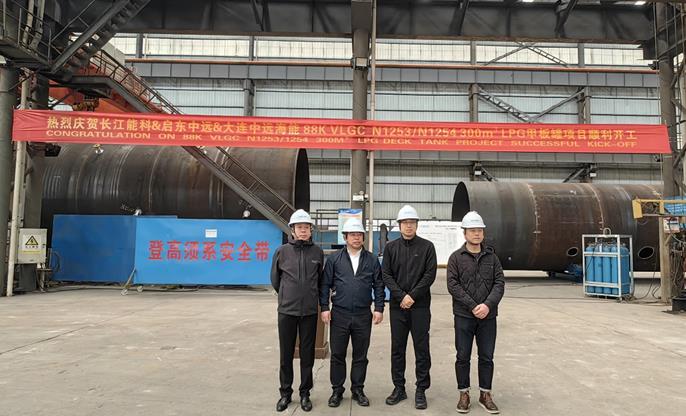

As the spring tide surges at the Changjiang estuary, intelligent manufacturing sets sail at the perfect time. Today, the first domestically built 88K VLGC (Very Large Gas Carrier) 300m³ deck tank project, jointly developed by SANTACC and COSCO SHIPPING (Qidong), officially commenced in Zhenjiang, Jiangsu. As a core piece of equipment filling a domestic technological gap, this project will propel China’s LPG carrier industry chain towards a new stage of independent development.

Breaking Barriers · Technological Breakthroughs: Setting a New Industry Benchmark from Three Dimensions

1.International Welding Process Certification

Successfully tackling 56 CCS (China Classification Society) certified welding processes, with 327 fatigue test datasets pushing the cyclic load limit beyond one million cycles, achieving a systematic breakthrough in LPG carrier deck tank welding technology in China.

2.Precision-Controlled Structural Design

After six months of technical iterations with CCS Shanghai Branch, 2,145 parameters were locked within safety thresholds, ensuring seamless integration between design and construction.

3.Full-Chain Quality Traceability System

Utilizing dual-certified special steel plates (CCS & LR) and establishing a 532-node ITP (Inspection & Test Plan) quality control network, enabling full traceability from steel plate sourcing codes to process validation, ensuring a closed-loop quality management system.

Collaborative Efforts · Ecosystem Co-Creation: Building a High-Quality Landmark through Tri-Party Synergy

• Strategic Leadership: COSCO SHIPPING (Qidong) deeply integrates marine engineering industry resources, forming a strategic resonance with SANTACC’s 30 years of expertise in specialized equipment manufacturing.

• echnical Assurance: CCS expert teams provide on-site guidance throughout the process, establishing a three-tier technical firewall—“Steel Plate Entry - Process Validation - Non-Destructive Testing” with international standards as the benchmark and specialized insights as the key.

• Breakthrough Execution: The project team completed 317 technical briefings and 12 process iterations in just 170 days, embodying “millimeter-level precision” to achieve “megaton-level responsibility.”

Intelligent Vision · Future Expedition: Leading the High-End Equipment Journey

• Smart Production Line: The first batch of intelligent welding robots has initiated parameter self-calibration, officially entering the intelligent manufacturing phase.

• Digital Twin: BIM models are mapped in real-time with physical construction, predicting over 98% of assembly risks in advance.

• Standardization Output: Simultaneously compiling the White Paper on the Construction Technology of Ultra-Large LPG Carrier Deck Tanks, driving the upgrade of industry standards.

Project Statement

“From the banks of the Changjiang to the deep blue ocean, every weld seam of the deck tank defines the precision scale of China’s equipment manufacturing." SANTACC’s General Manager, Liu Jiacheng, remarked, "Let us forge an exceptional project with the will of steel and illuminate the future of marine equipment with intelligent welding craftsmanship!"

Previous:None

Next:SANTACC’s Middle East Business Visit Yields Fruitful Results